Best Quality and Advanced Technology for our Customers

Electrolytic Application

-

Safe!

Device replacing dangerous chlorine gas

Chlorine gas is classified as toxic gas, requiring safety manager, and serious damage can occur in case of leakage. Meanwhile, high density subchloride generator is safe because of direct production of high density (5~15%) liquid subchloride aqueous solution as necessary on site. -

Stable!

Stable production and injection with site generating type device

Subchloride with target density with low by-products can be stably produced and injected in comparison with existing subchloride solution, by direct production and supply on site. -

Excellent economic feasibility!

It saves maintenance and device operation expenses

In comparison with low density subchloride generator consumption of salt as required material for device operation (50%) and electric energy (25% or more) can be saved. -

Convenient!

Simple and convenient operation

By supplying salt and electricity only without replacing dangerous chlorine container, stable integrated operation and sterilization process are automated, so anybody can operate it with a simple touch. -

Strong!

Superb sterilization capacity with dramatic reduction of sterilization by-products

As chlorine generated at positive pole and caustic soda generated at negative pole are separately gas-liquid contacted to respond and to generate by-products using septate electrolysis method, sterilization by-products such as chloride(CIO3-) and bromate (BrO3-) have been reduced by 90% or more in comparison to existing low density subchloride facilities. -

Superior applicability!

Replacement sterilant applicable to large scale purification plant

As high density subchloride solutions are generated, it can be applied to large scale capacity metropolitan purification plant that mandatorily requires chlorine substitution. This is a device indispensable to any process to which large scale capacity subchloride aqueous solution is to be applied.

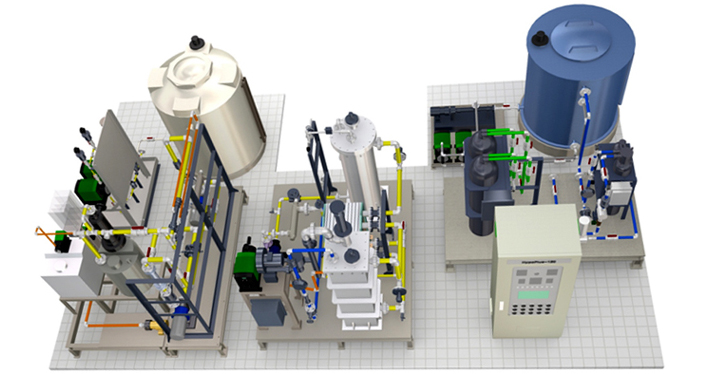

HypoPlus composition chart

HypoPlus high density subchloride generator is a sterilization process applying independent and innovative technologies.

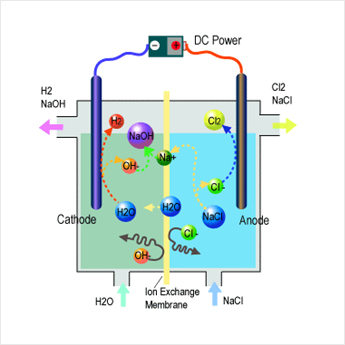

Electrochemical reaction

- anodic reaction : 2CI- вЖТ CI2 + 2e- / 2H2O вЖТ 4H + O2 + 4e-

- cathodic reaction : 2H2O + 2e- вЖТ H2 + 2OH-

- generating reaction : 2Na+ + 2OH- вЖТ 2 NaOH / CI2 + 2NaOH вЖТ NaOCI + NaCI + H2O

Subchloride generating concentration

- 5~12%(50~120G/L)

Electricity consumption

- 3.5 KW-HR / KG-CL2

Consumption of salt

- 1.75 KG / KG-CL2

Chloride generation amount

- 0.002~0.006PPM

HypoPlus high density subchloride generator is an innovatively developed product, which enjoys high quality.

Innovatively developed product

-

Reduced maintenance cost

-

Use of salt reduced by 50%

3.7 вЖТ 1.8 kb-NaCI/CI2

-

Electricity cost reduced by 25%

4.6 вЖТ 3.5 DC-kWh/kg-CI2

-

Transfusion ratio reduced in comparison with chlorine

125 times вАУ Max. 8 times

-

-

Reduced inorganic by-product

-

Chloride (CIO3-) reduced by 90%

0.1 вЖТ 0.01 ppm-[CIO3-] / ppm-[CI2]

пЉЭ> [CI2] Transfusable concentration = Max. 70ppm -

Bromate (BrO3-) : source blocked

Note) Legal standard by the Ministry of Environment

[CIO3] вЙ§ 0.7ppm, [BrO3-] вЙ§ 0.01ppm

-

-

Reduced natrium contents

-

Natrium contents reduced by 52%

1.47 вЖТ 0.17g-[Na+]/g-[CI2]

Note) Factors affecting taste of water (Professor Hashimoto, Japan)

k index = [Ca] 0.87X[Na]

-

HypoPlus provides a new vision that you have never experienced before.

-

Chlorine transfusion

facilities- Chlorine smell causes concern of civil complaints

- In case of leakage, large scale mortality accident occurs

- Complex composition of facilities and high corrosiveness

- Disadvantageous to automation (manual replacement of chlorine container)

Commercialized water treatment technology -

Low concentration

subchloride generator (0.8%)- Mainly applied to medium, small facilities due to economic feasibility

- No legal restriction, superb control function

- Simple composition of facilities and easy maintenance

- Inorganic by-products generated and economic feasibility problem

localization of sterilization facilities -

arrow_downward

High density subchloride

generator (12%)- Overcame limitation in capacity (applicable to metropolitan water supply)

- Generation of inorganic by-products minimized in comparison to existing subchloride

- Easy maintenance and reduced management expenses

- Stable integrated operation and automation function of sterilization process

TECHWIN

TECHWIN TECHWIN

TECHWIN