Best Quality and Advanced Technology for our Customers

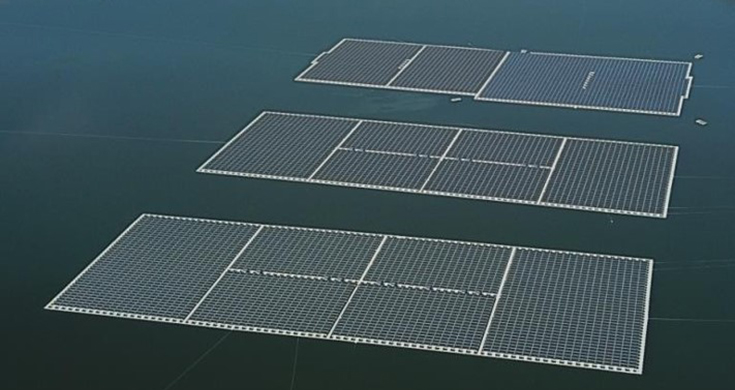

Buoyant Material for Floating Photovoltaic System

Thank you for visiting the homepage of Techwin Co.,Ltd

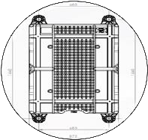

Eco frame buoyancy structure

Introduction to energy business

- Buoyant material production and sales

- EPC business

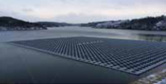

Floating photovoltaic power plant business

- Domestic EPC: 9MW commercial operation + 23MW licensed and permitted, preparation for construction

- Export: 4MW (Belgium, Australia, Japan, Singapore, etc.)

| Manufacturing plant | Factory view (Size of 20,000 square meters) |

|---|---|

|

|

| Head count 20 persons Production quantity 400MW/year (April 2019~) |

Natural disaster & disaster stability

Durability to ultraviolet rays

- 20 year life verification completed in 2017

пЉК UV durability experiment implemented at Japanese laboratory - Prevention of hardening by adding 3% of special UV stabilizer

- 20 year life verification completed in 2017

Stability when in contact with water bottom in dry season

- dredging construction/ 1/8 of frame type buoyancy structure compressive load in response to drawdown in farming season

пЉКOur company 15kg / frame type 120kg

- dredging construction/ 1/8 of frame type buoyancy structure compressive load in response to drawdown in farming season

Safety against heavy snowгЖНfreezing

- Experiment result

15вДГ below zero, ice thickness 25cm : no damage and deformation of buoyancy structure

Snowfall load : 0.78kN/ гО° (amount of snowfall: 55cm)

- Experiment result

Safety against typhoon & wave height

- Experiment result

wave height: strength maintained at 93% of 360,000 times

typhoon: stability proven at 210km/h

пЉКFrance ONERA laboratory

- Experiment result

Preventing corrosion & safety against concentrated load

Buoyancy structure

- eco-friendly high density polyethylene with strong corrosion resistance, corrosion resistance ensured against salt water, hardening prevented by adding 3% of special UV stabilizer

Clamp and catenary cable :

- oxide coated aluminum & stainless steel applied вЖТ corrosion resistance and durability enhanced

Connecting pin

- reinforced polypropylene material applied, about 14,000 connecting pins used based on 1MW , designed load designed within standard of 1,000kgf/EA гЖНLowest determined load 1,300kgf/EA based on 10вДГ below zero

Catenary supporting base (supporting buoyancy structure & catenary cable)

- designed based on design load of 2,000kgf/EA

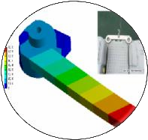

- пЉК designed as crack load of 4,500kgf/EA based on computer simulation

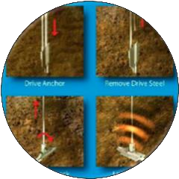

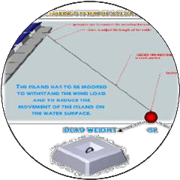

Stability & quality guarantee of mooring device

1. Exact southbound direction maintained despite change in maximum water level

- Change in water level + excess water level (1~1.5m)

- Design and construction with anchor mooring angle 30 degree or less

- Easily recovering structure after touching bottom of reservoir

2. Quality guarantee

- Quality guarantee for Techwin buoyancy structure is provided for 15 years.

- Expected life of buoyancy structure is 25 years or longer

3. Wind tunnel experiment/CFD analysis by France ONERA laboratory

- By combination of wind tunnel experiment+computer flow analysis

- Wind tunnel coefficient calculation & design is applied

- Durability against typhoon : 210km/h (58.3m/sec)

-

4. Earth anchor constructed which is directly fixed to the floor

- concrete heavyweighted item X вЖТ concern on maintenance & environment X

- Risk of collision with water surface structure in case of low water level X

- Anchor of more than 1 times of total resistance needed to be purchased

-

Weight pendulum method

- Concrete heavyweighted item O вЖТ concern on maintenance & environment O

- Risk of collision with water surface structure in case of low water level

- Heavyweighted item of 1.7 times of total resistance required пЉКIn case of 2~3 grade wave zone, chain and anchor installed

Domestic performance

- 9MW system connected commercial operation at 8 sites

- 23MW construction works have been licensed, permitted and in progress at 9 sites

Overseas performance

- 280MW commercial operation at 140 sites

- 95MW under construction at 145 sites

| Japan | ||||

|---|---|---|---|---|

|

|

|

|

|

| OKEGAWA - 1,180 kWp | KATO-SHI - 2,870kWp | UMINOKI - 7,550 kWp | TANO IKE - 2,552 kWp | |

| EUROPE | ||||

|---|---|---|---|---|

|

|

|

|

|

| SHEEPLANDS, UK - 200 kWp | POLYBELL, UR - 471 kWp | GODELY, UK - 2,991 kWp | PONTECORVO, ITALY - 343kWp | QE2, 6,338 kWp |

| AMERICAS | ||||

|---|---|---|---|---|

|

|

|

|

|

| ORLANDO, USA - kWp (extension 900kWp) | KUNDE, USA - 10 kWp (exension 744 kWp) | MIRAFORES, PANAMA - 24kWp | ORLANDO UTILITES, USA - 32 kWp | PENOL GUATAPE, COLOMBIA - 99kWp |

| ASIA | ||||

|---|---|---|---|---|

|

|

|

|

|

| O CHAN, SOUTH KOREA - 495 kWp | ULU SEPRI, MALASIA - 270 | AGONGDIAN, TAIWAN - 2,320 kWp | LIMORE, AUSTRAILA - 100kWp | AHUI CECEP, CHINA 70,005 |

- The largest size/number of designs, construction performance held all over the world

- Superior durability and stability against typhoon have been proven (2013~2018 Japan)

- WorldвАЩs first installation at drinking water source (Thames River drinking water source, 6.4MW in U.K.)

TECHWIN

TECHWIN TECHWIN

TECHWIN