Best Quality and Advanced Technology for our Customers

Water Treatment Facilities

Thank you for visiting the homepage of Techwin Co.,Ltd

- Air Pollution Control

- Solvent Recovery System

- Water Treatment Facilities

- Treatment of Power Plant Water

- Wastewater Treatment

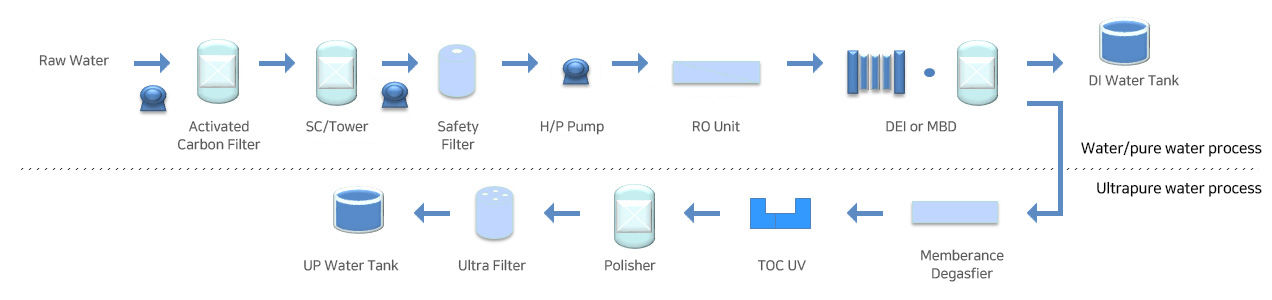

Pure water/ultrapure water production facilities

General System composition for pure water/ultrapure water

- Diverse facilities can be composed according to the targeted water quality, but in case of normal water, up to Make-up System are composed. In case water quality over pure level is targeted, Polishing System is composed

-

STEP 1

Raw

Water -

STEP 2

Pretreatment

System -

STEP 3

Make-up

System -

STEP 4

Polishing

System

| Process | Function and representative facilities | |

|---|---|---|

| Pre Treatment System |

|

|

| Make Up System |

|

|

| Polishing System |

|

|

Pre-treatment facilities

| Facilities | MMF (Multi Media Filter) |

ACF (Activated Carbon Filter) |

DAF (Dissolved Air Flotation) |

MF (Micro Filter) |

UF (Ultra Filter) |

|---|---|---|---|---|---|

| Function |

|

|

|

|

|

| Characteristics |

|

|

|

|

|

| image |  |

|

|

|

|

| Facilities | ||

|---|---|---|

| Function | Characteristics | image |

| MMF (Multi Media Filter) | ||

|

|

|

| ACF (Activated Carbon Filter) | ||

|

|

|

| DAF (Dissolved Air Flotation) | ||

|

|

|

| MF (Micro Filter) | ||

|

|

|

| UF (Ultra Filter) |

||

|

|

|

Composition of pure water/ultrapure water facilities

| Process | Contents | |

|---|---|---|

| Pure water process | ACFгЖНSC/Tower | Major hardness components such as suspended solids, organic matters, Ca2+гЖНMg2+removed |

| RO UnitгЖНIon Ex | Fine salts and various ions removed | |

| Ultrapure water process | Degasfier | Gaseous component within water removed |

| UVгЖНPolisher | TOC ingredients removed to prevent proliferation of germs, minimum organic matters and inorganic matters removed | |

| Ultra Filter | Last alien substance that can exist removed | |

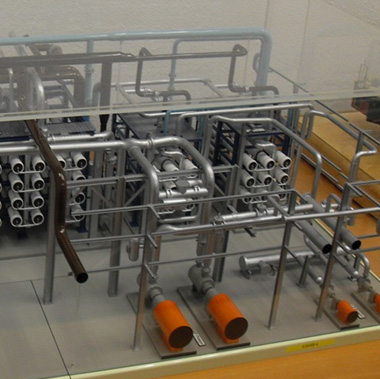

Seawater desalination facilities (Sea water treatment)

Composition of seawater desalination facilities

-

STEP 1

Seawater

INTAKE -

STEP 2

pre-treatment facilities

(MMF, ACF, MF, UF) -

STEP 3

SWRO + ERD

-

STEP 4

BWRO

Technology description

- The system facility using RO membrane to remove ions within the water by filtering water through the membrane with high pressure

- Desalination facilities with highly efficient ion removal ratio at 99% or higher

- Operation expense can be saved using energy efficient device (ERD)

- Stable quantity of treated flow secured without blockage during mid to long term operation by regular cleansing (CIP)

-

INPUT Quality of original water

- Turbidity/SS

- TDS

- Mg2+гЖНCa2+ (Major scale ingredients)

- B

- Na+,Cl- B

- Temperature. pH

- Production quantity

- Quality of produced water

-

OUT PUT

- Pre-processing system

- Amount of medicines used (Bio Fouling, Scaling, Cl2 revivification)

- Recovery ratio RO system composition

-

- Quality of processed water

- Specification/quantity of tools and materials

- Area of installation

- Facilities cost

- Expected production cost of water

System design

- Optimal combination of minimum capital expenses (facilities cost) with minimum operation expenses by process

- Experimental design technologies such as compact design and RO Membrane placement/arrangement design are required.

- Decision factors for experimental design are important elements for deciding facilities and operation cost

- Pre-treatment SYSTEM is determined by turbidity/SS level, and recovery ratio is adjusted according to ingredients/ level of TDS and RO contaminants

Installation performance LIST

Water Treatment

Recycled water treatment

Reuse of sewage, wastewater

Reuse of sewage, wastewater

- The business of treating sewage or wastewater for recycling using recycling facilities for sewage/wastewater, and supplying such treated water

Flow

-

STEP 1

Sewage/wastewater effluent

-

STEP 2

pre-treatment facilities

(MMF, ACF, DAF,

fiber filter) -

STEP 3

MAIN SYSTEM

(MF + RO

or UF + RO) -

STEP 4

follow-up treatment

(electrolysis/UV / Ozone)

- Optimal for quality guarantee of recycled water, by completely removing contaminants including ions within original water by osmosis pressure treatment process

- Convenient operation and maintenance due to simple structure and PLC automated operation

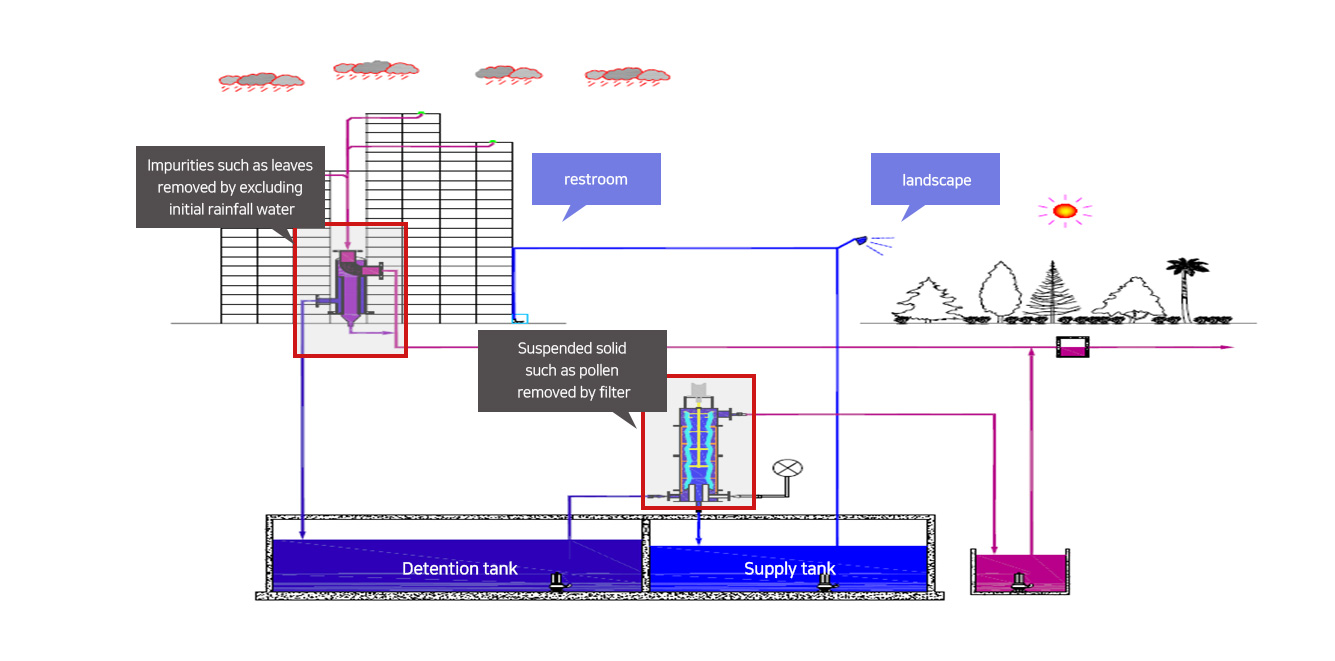

Recycling of rainwater

- The business of gathering and treating rainwaters falling on roof of buildings for use, and supplying such treated water

TECHWIN

TECHWIN TECHWIN

TECHWIN